Process Step # 1: Four (4)-Stage Pre-Wash

Stage 1: Alkaline Cleaner

Cleans steel surfaces of anti-corrosion oils, added by the steel producer.

Stage 2: Reverse Osmosis

pH Water Rinse

Technically this process contains two (2) stages. The first sprays high pH water to remove any alkaline residues. The second stage sprays low pH water to remove and acidic residues.

Stage 3: Nano-Ceramic Zirconium Treatment

Helps with paint adhesion and corrosion protection (preventing oxidation while unpainted), while reducing the environmental impact.

Stage 4: Reverse Osmosis

Water Rinse

Like the streak-free rinse in a car wash, the halo rinse is the final rinse to remove any remaining contaminants from previous stages.

Process Step #2: Dry-Off Oven

Our dry-off oven ensures parts are dry prior to the powder coat application. If water is present during powder application, water marks and imperfections will appear in the paint finish.

Process Step #3: Electrostatic Powder-Coat Application

Electrostatic powder-coat is achieved by applying an electrostatic charge to the powder particles which are attracted to a grounded part. Spray guns are used to apply the paint using both automatic and manual techniques.

Process Step #4: Powder Coat Bake Oven

Our bake oven cures the powder into a seamless coating. Our bake oven consists of a 33ft infra-red oven booster that brings the part up to the required cure temperature. The remaining 179ft is a convection bake oven that maintains a steady baking temperature of 400 degrees.

More About the Powder Coat Process

Is the Finish

Rust-Proof?

When applied to mild steel and installed in a non-corrosive environment, the powder coat paint process holds up better than wet paint. UL/CSA Type 4 products are subjected to a 600 hour salt spray test.

The Nano-ceramic coating applied during the wash process helps with corrosion protection. In addition, a fully painted product resists external elements from corroding the base material.

Powder coated products are more resistant to diminished coating quality from impacts, moisture, chemicals, ultraviolet light and extreme weather conditions.

What is the Powder?

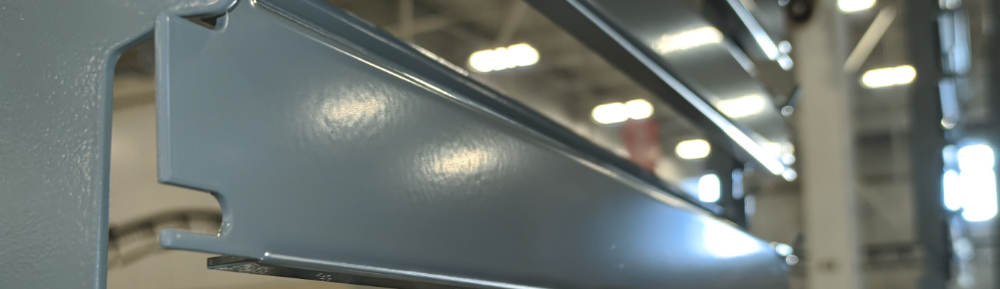

During the baking process the polymer resin powder melts coating the sheet metal and binds the polymer into a tighter and denser finish.

Powder coating provides a more durable and longer lasting finish compared to conventional wet painting. Also, powder coating is typically a one-coat finish.

How Durable is the Finish?

Environmental Benefits

Paint Reclaim

Every year, Hammond reclaims 85% of paint used. Our paint process includes the ability to re-use (reclaim) paint that misses the product in the paint booth. This process keeps 146,200 kg of waste paint from ending up in landfill.

Water Treatment

Approximately 98% of water used in our paint process is recovered and reused. The remaining 2% is treated in-house to exceed municipal standards.

No Chemical Exposure

Unlike wet spray-painting environments, our powder coat paint process does not off-gas any fumes or chemical exposure making it ideal for education, healthcare and office applications.

Download our Powder Coat Finish Guide

See our in-stock and easy-order paint options available.